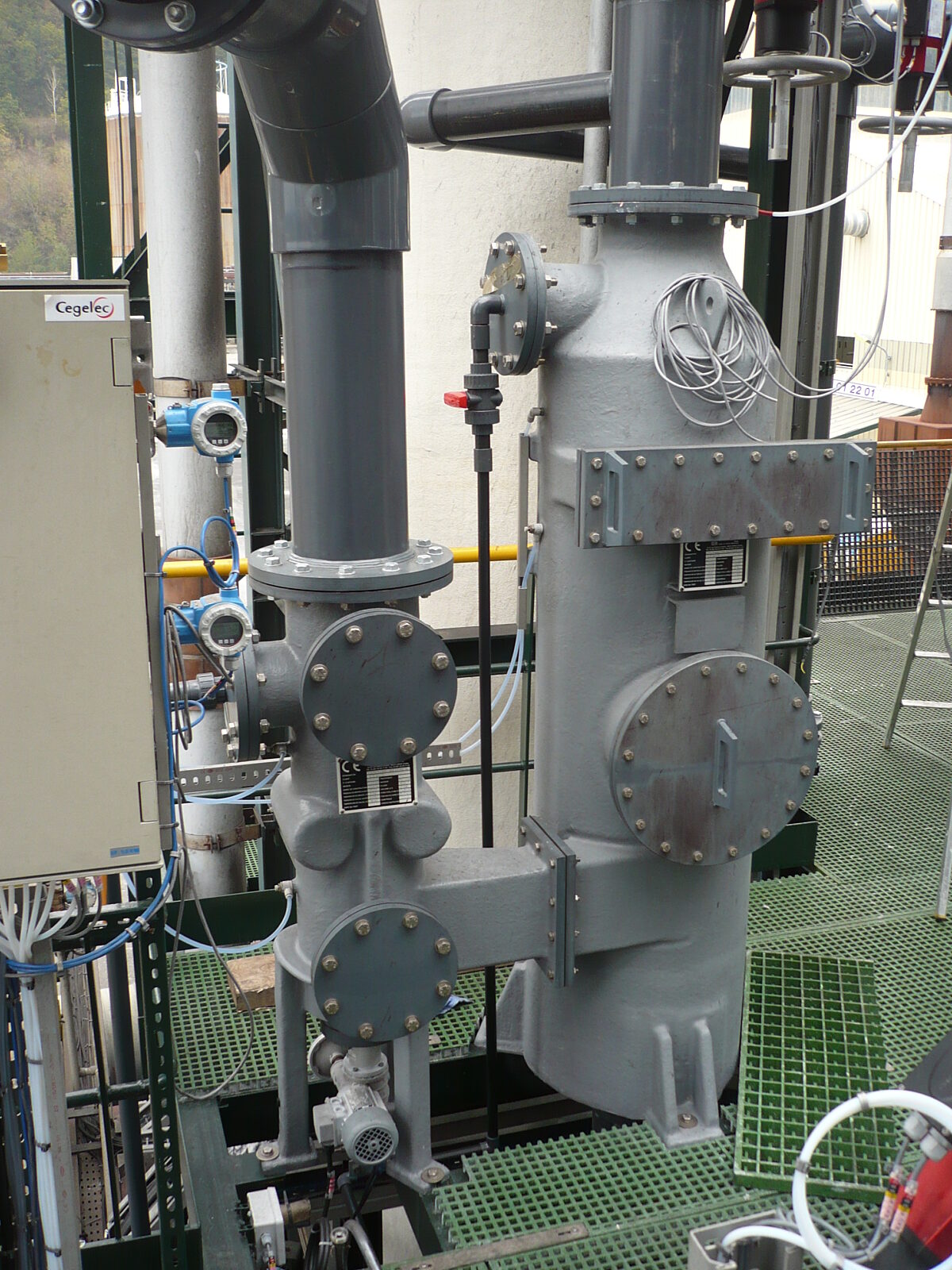

Reither® venturi scrubber

High-performance venturi scrubber technology

Separation of finest particles

The SOCREMATIC venturi scrubber range includes the REITHER® and Hybrid REITHER® venturi scrubber solutions.

The venturi scrubber system REITHER® is a high efficiency wet scrubber design, suitable for separation of particles down to the submicron range. It is simple in its design and suitable for variable waste gas flow rates due to the adjustment of the Venturi throat. In a centrifugal mist eliminator adjacent to the contact zone, the scrubbing liquid droplets are removed from gas flow.

REITHER® Venturi scrubber

The REITHER® venturi scrubber is designed for efficient separation of the finest dust aerosols. It is equipped with an adjustable venturi throat cross section which maintains a constant pressure drop across the throat and allowing a constant separation efficiency, independent of any flow rate fluctuation.

REITHER® Venturi scrubbers are particularly effective at removing particles from 0.3 to 50 µm at very high efficiencies. New technology in venturi scrubbing of flue gas particulates, and aerosols achieves removal efficiencies up to 99% on particles and aerosols down to 0.3 µm. At the sub-micron zone, the principle of venturi scrubbing forces the contact of the particle with fine water droplets.

REITHER® Venturi scrubber capacity and advantages

Capacity REITHER®:

- Gas flow: up to 200 000 m³/h

- Particle size distribution: > 0.5 µm

- Dust concentration: < 2 g/m³

Advantages REITHER®

- Simple and compact design

- Cost effective

- High collection on superfine dusts and aerosols with low pressure drop

- Controllable on different flow patterns, dust loads, ...

- Simultaneous absorption of gaseous pollutants possible

- Non-clogging

More on sub-micron particulate removal

Contact us today and discover what our range of REITHER® venturi scrubbers can do for you.