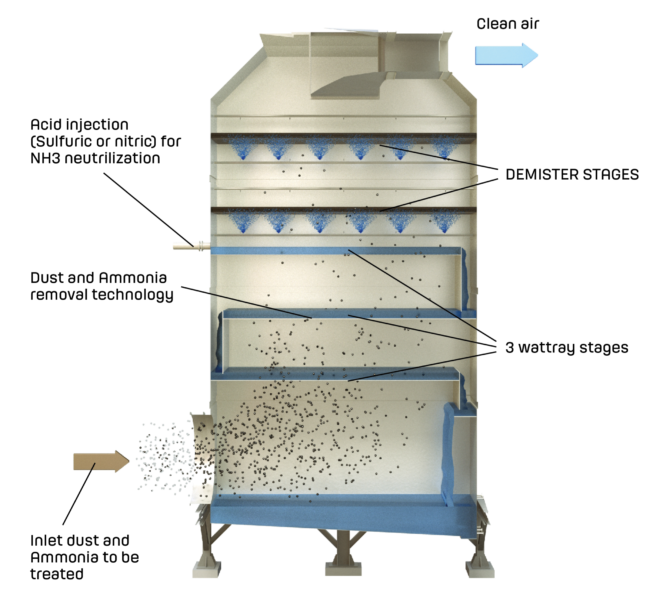

WATTRAY® tray scrubber

Socrematic's Fixed Valve Tray scrubber with demisting functionality

Your best option for dust removal in the ferilizer industry

The WATTRAY® scrubber is SOCREMATIC’s tray scrubber technology using fixed valve trays in combination with multiple layer WATMESH® bone crimp demisters and is particularly adapted for :

- Urea dust removal in exhaust of fluidized bed urea granulation plants

- Calcium ammonium nitrate fluidized bed exhaust

- Urea and ammonium nitrate prilling tower exhaust

The fixed valve tray is a combination of the characteristics of a tray with movable valves and a sieve tray. In addition to its high resistance to soiling, the SOCREMATIC WATTRAY® scrubber is characterized by its high capacity and separating

efficiency

Fixed valve tray gas-liquid contactor

Dedicated to urea dust removal, the WATTRAY® scrubber will be typically installed as to reduce the urea dust particles remaining in the off-gas from the fluidized bed granulator, final cooler exhausts off gas.

This technology consists in a vertical crosscurrent gas-liquid contactor containing two Fixed Valve Tray type. The said trays provide the intimate contact between the gas phase containing urea dust particles and the aqueous urea diluted recovered solution.

The recirculated UAS (Urea + Ammonium Sulphate) solution enters the WATTRAY® scrubber at the top of the urea section and flows downward by gravity.

On its way, it flows horizontally across from top tray through a down comer to the tray below while the gas flow enters crosscurrent the scrubber at the bottom and is directed upwards through the openings provided by the valve trays.